Sn99Cu0,7Ag0,3 EVO

Product name: Sn99Cu0,7Ag0,3 EVO

Alloy designation in accordance with ISO 9453:2014:

Sn99Cu0,7Ag0,3 (501)

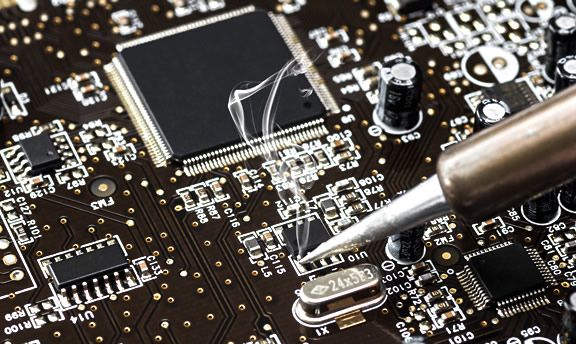

Product type: Cored solder wire

Flux: EVO

1. General characteristics

The solder was produced in the first smelt of tin, silver and copper. The composition of the solder complies with the ISO 9453:2014 standard. EVO solid flux is a “no clean” and based on rosin. The flux EVO is intended for manual and automatic soft soldering. The solder wire meets the requirements of the RoHS2 Directive.

2. Chemical compositions, mass fraction in %

| Sn | Ag | Cu | Pb | Sb | Bi | Cd | Au | In | Al | As | Fe | Ni | Zn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| rest | 0,20 - 0,40 | 0,50 - 0,90 | max 0,07 | max 0,10 | max 0,006 | max 0,002 | max 0,005 | max 0,10 | max 0,001 | max 0,03 | max 0,02 | max 0,01 | max 0,001 |

3. Physical characteristics

| Melting point: (solidus / liquidus) | 217 / 227°C |

| Density | 7,33 g/cm3 |

| Electrical conductivity | no data |

| Thermal conductivity | no data |

| Tensile strength | 300 kgf/cm2 |

| Elongation at break | 22 % |

| Hardness | 14 HB |

| Suggested operating temperatures | 340 - 420°C |

4. EVO flux

| acc. to DIN 8511 | SW26 |

| acc. to ISO 9454 | 1.1.2B |

| acc. to J-STD-004 | ROL1 |

| Flux content | 3,0 +/- 0,2% other on request |

| Halide content | 0,5 % |

| Acid Value | 195 ±10 mg KOH/g |

| SIR test (PN-EN ISO 9455-17) | pass (above 100 MΩ) |

5. Other information

| Available diameters |

0,25 • 0,38 • 0,50 • 0,56 • 0,70 • 0,80 • 0,90 • 1,00 • 1,20 • 1,50 • 1,60 • 2,00 • 2,50 • 3,00 • 4,00 mm other on request |

| Packed |

50 g – cartons 120 pcs. other on request |

| Expiration date | 3 years from the end of the year of production. for example: batch 61112233 = date of production 2016, date of expiry 2019 |

| Label | Reels and cartons marked with alloy type, flux type, diameter, net weight and batch number. |

| Storage | Store at room temperature, in a dry place and beyond the reach of children. |

Files to download:

Processes

Reflow Soldering

Wave Soldering

Selective Soldering