Sn99Cu0,7Ag0,3

Low silver (LOW-SAC) lead-free alloy in the form of solder bars, rods and wire for soldering applications in soldering aggregates.

Product name: Sn99Cu0,7Ag0,3 (SAC0307, TSC)

Alloy designation in accordance with ISO 9453:2014:

Sn99Cu0,7Ag0,3 (501)

Product type: solder bars and rods, solder wire

1. General characteristics

The solder was produced in the first smelt of tin, silver and copper. The use of a continuous casting process ensures minimization of the generation of oxides in the solder. As a result, the phenomenon of the formation of dross in the soldering process is significantly reduced. The composition of the solder complies with the ISO 9453:2014 standard. The solder wire and bar meet the requirements of the RoHS2 Directive.

2. Chemical compositions, mass fraction in %

| Sn | Ag | Cu | Bi | Sb | Cd | Au | In | Pb | Al | As | Fe | Ni | Zn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| rest | 0,20 - 0,40 | 0,50 - 0,90 | max 0,06 | max 0,10 | max 0,002 | max 0,05 | max 0,10 | max 0,07 | max 0,001 | max 0,03 | max 0,02 | max 0,01 | max 0,001 |

3. Physical characteristics

| Melting point: (solidus / liquidus) | 217 / 227°C |

| Density | 7,33 g/cm3 |

| Electrical conductivity | no data |

| Thermal conductivity | no data |

| Tensile strength | 300 kgf/cm2 |

| Elongation at break | 22 % |

| Hardness | 14 HB |

| Suggested operating temperatures | 250 - 350°C |

4. Other information

| Available diameters |

• 0,50 • 0,80 • 1,00 • 1,20 • 1,50 • 2,00 • 3,00 other on request |

||||||||||||

| Available cross-sections and sizes of bars and rods |

other on request |

||||||||||||

| Expiration date | not applicable | ||||||||||||

| Label | The product is marked by a type of alloy or acc. to customer requirements. Cartons, reels marked with a type of alloy, sizes, lot number and net weight. |

||||||||||||

| Storage | Keep away from strong oxidizing agents, acids and alkaline agents. The recommended humidity level is 20-60% and temperature is 5 – 20 °C. |

Files to download:

Processes

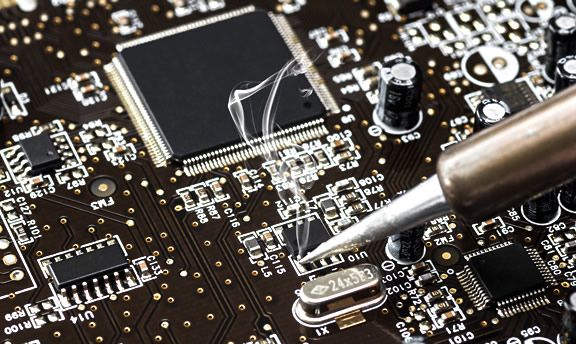

Reflow Soldering

Wave Soldering

Selective Soldering