Sn63Pb37

The basic lead solder alloy in the form of solder wire, rod and bar for soldering applications in soldering aggregates where it is not required to meet the RoHS2 requirements.

Alloy designation in accordance with ISO 9453:2014:

Sn63Pb37 (101)

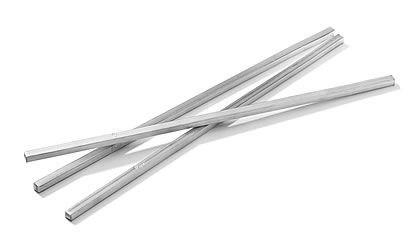

Product type: Solder bars and rods, Solder Wire

1. General characteristics

The product is intended for professional use. The solder Sn63Pb37 was produced in the first smelt of tin and lead. The composition of the solder complies with the ISO 9453:2014 standard. It is basic leaded alloy for manual, automatic and robotic processes used in industrial applications in electronics and electrical engineering, where meeting the requirements of the RoHS2 Directive is not required.

2. Chemical compositions, mass fraction in %

| Sn | Pb | Sb | Bi | Cd | Cu | Au | In | Ag | Al | As | Fe | Ni | Zn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 62,50 - 63,50 | rest | max 0,05 | max 0,05 | max 0,002 | max 0,08 | max 0,05 | max 0,10 | max 0,10 | max 0,001 | max 0,03 | max 0,02 | max 0,01 | max 0,001 |

3. Physical characteristics

| Melting point (solidus/liquidus) | 183°C |

| Density | 8,40 g/cm3 |

| Electrical conductivity | 0,145 μΩ•m |

| Thermal conductivity | 50 W/m•K |

| Tensile strength | 525 kgf/cm2 |

| Elongation at break | 37% |

| Hardness | 17 HB |

| Suggested operating temperatures | 250 - 270°C |

4. Other information

| Available diameters |

• 0,50 • 0,80 • 1,00 • 1,20 • 1,50 • 2,00 • 3,00 mm other on request |

|||||||||||||||

| Available cross-sections and sizes |

other on request |

|||||||||||||||

| Expiration date | not applicable | |||||||||||||||

| Label |

The product is marked by a type of alloy or acc. to customer requirements. Cartons, reels marked with a type of alloy, sizes, lot number and net weight. |

|||||||||||||||

| Storage | Keep away from strong oxidizing agents, acids and alkaline agents. The recommended humidity level is 20-60% and temperature is 5 – 20 °C. |

Files to download:

Processes

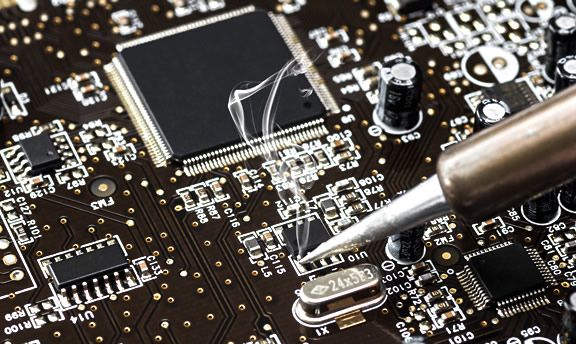

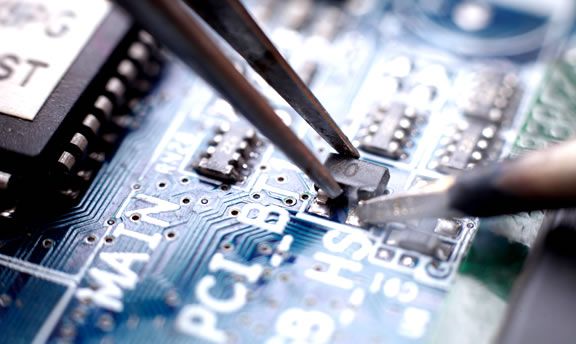

Reflow Soldering

Wave Soldering

Selective Soldering