Sn99Cu0,7Ag0,3 1.1.3

Product name: Sn99Cu0,7Ag0,3 1.1.3

Alloy designation in accordance with ISO 9453:2014:

Sn99Cu0,7Ag0,3 (501)

Product type: Cored solder wire

Flux: 1.1.3

1. General characteristics

The solder was produced in the first smelt of tin, silver and copper. The composition of the solder complies with the ISO 9453:2014 standard. 1.1.3 solid flux is based on rosin and halide free formulations. Low silver lead-free alloy is intended for professional mechanized soldering in electronics where meeting the requirements of the RoHS2 Directive is required.

2. Chemical compositions, mass fraction in %

| Sn | Ag | Cu | Bi | Sb | Cd | Au | In | Pb | Al | As | Fe | Ni | Zn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| rest | 0,20 - 0,40 | 0,50 - 0,90 | max 0,06 | max 0,10 | max 0,002 | max 0,05 | max 0,10 | max 0,07 | max 0,001 | max 0,03 | max 0,02 | max 0,01 | max 0,001 |

3. Physical characteristics

| Melting point: (solidus / liquidus) | 217 / 227°C |

| Density | 7,33 g/cm3 |

| Electrical conductivity | no data |

| Thermal conductivity | no data |

| Tensile strength | 300 kgf/cm2 |

| Elongation at break | 22 % |

| Hardness | 14 HB |

| Suggested operating temperatures | 340 - 420°C |

4. 1.1.3 flux

| acc. to DIN 8511 | SW32 |

| acc. to ISO 9454 | 1.1.3B |

| acc. to J-STD-004 | ROM0 |

| Flux content | 3,0 +/- 0,2% other on request |

| Halide content | 0,0% |

| Acid Value | 195 ±10 mg KOH/g |

| SIR test (PN-EN ISO 9455-17) | no data avaliable |

5. Other information

| Available diameters |

0,25 • 0,38 • 0,50 • 0,56 • 0,70 • 0,80 • 0,90 • 1,00 • 1,20 • 1,50 • 1,60 • 2,00 • 2,50 • 3,00 • 4,00 mm other on request |

| Packed |

50 g – cartons 120 pcs. other on request |

| Expiration date | 3 years from the end of the year of production. for example: batch 61112233 = date of production 2016, date of expiry 2019 |

| Label | Reels and cartons marked with alloy type, flux type, diameter, net weight and batch number. |

| Storage | Store at room temperature, in a dry place and beyond the reach of children. |

Files to download:

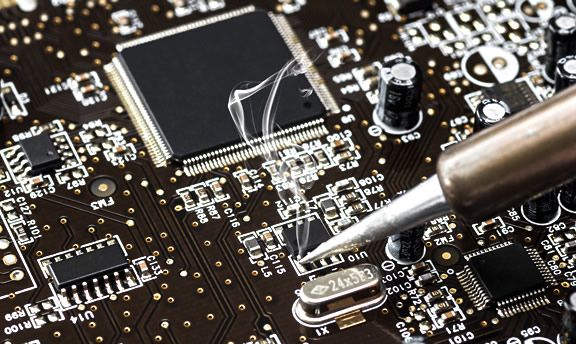

Processes

Reflow Soldering

Wave Soldering

Selective Soldering