Services

Analysis of metal alloys

The quality policy implemented by Cynel-Unipress requires the whole production process, starting from the stage of supplying raw materials to confectioning of finished products, to be subjected to strict control.

One of the elements of the quality control system is to monitor the chemical composition of alloys. For this purpose, we use the spectrophotometric analysis. It is one of the most modern analytical technologies and the received results are very precise.

Until now, this technology has been used exclusively for the internal needs of our company. However, in order to meet the needs of some of our Clients, we decided to share the capabilities of our measuring equipment.

We invite you to use the services we provide in this area. We guarantee high quality as well as reliability and credibility of the results of the research obtained, affirmed by a certificate issued.

Please contact our Marketing Department if you have any questions regarding our services.

Consulting of production technology

Cynel Unipress has been involved in the production of multi-core and monolithic binders for soldering, offering a wide range of types of alloys and fluxes since 1984. We owe our technology of production of this type of adhesives to specialists of the Department of High Pressure Physics, Polish Academy of Sciences.

Over the years we have gained experience and expertise that today allow us to provide services at an appropriate level. To a large extent it is also the merit of our customers, who together with us have been looking for solutions to emerging technological problems. It is thanks to ever-increasing demands and expectations of our clients that Cynel Unipress is today a leading manufacturer in the industry, and our efforts and striving to continuously enhance the quality of our products and services have been awarded the Certificate of Quality, System ISO 9001.

We will be honored to share our knowledge and experience with you as well as to assist you in improving your manufacturing technologies using solder technique.

Our specialists are at your service.

If you have any questions in this regard, please contact our Marketing Department.

Spectrophotometry - how it works?

Any solid, liquid or gas substance respectively energized emits radiation at different wavelengths. This radiation is characteristic of the substance and form of its spectrum.

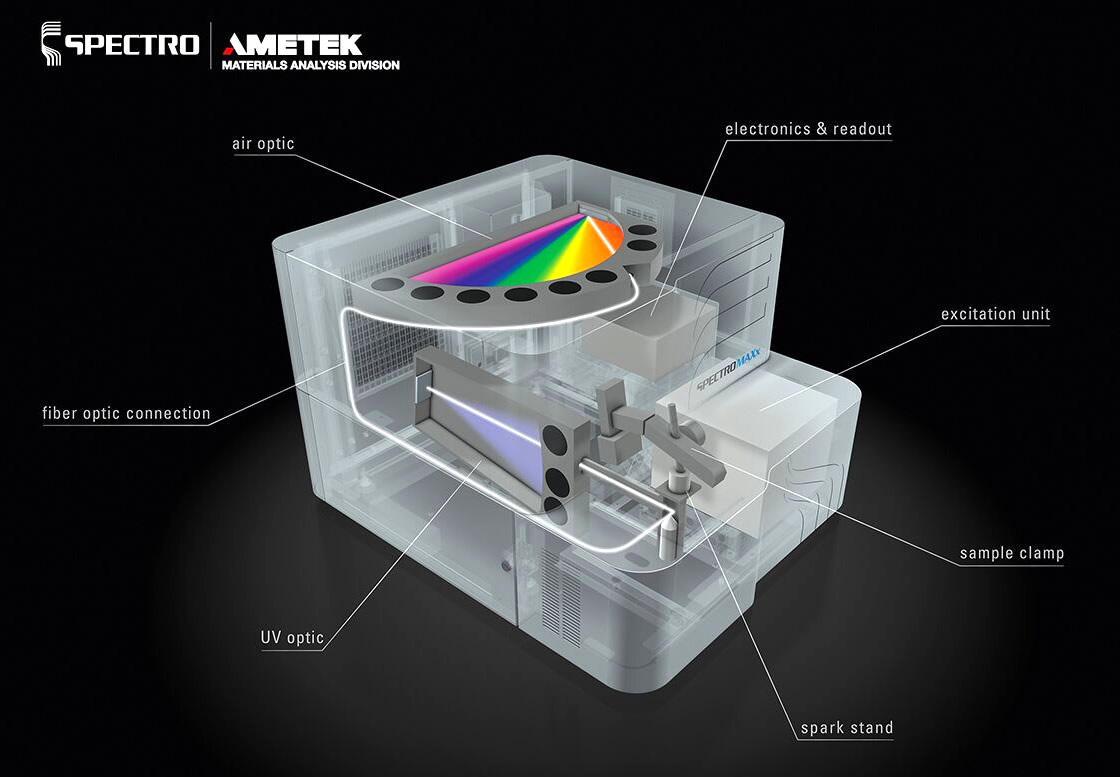

The emission spectrometer used by Cynel Unipress analyzes the spectrum of tested samples, i.e. identifies and measures the radiation emitted by them and on that basis determines their chemical composition.

The spark of the high voltage raises and causes evaporation of the material, whose composition must be determined. Light emitted in this process includes the radiation of different elements present in the analyzed material. The light intensity of each spectral line is proportional to the concentration of the element which emitted them.

The spectrometer divides and selects different spectral lines to be analyzed as well as determines their quantity.

Polichromator is an essential device in whole proccess.

A polichromator consists of an entrance slit, a diffraction grating, and a number of output slits, which correspond to the volume of the analyzed elements.

Photomultiplier set correctly for each output slit captures and measures the quantity of selected monochromatic light and converts it into an electrical signal, which is fortified and converted into a digital signal. On its basis, a computer calculates the concentration of different elements.

The calibration is carried out according to certified standards. Introducing curves and defining interfering elements takes place automatically without user’s intervention.

Thanks to this, analyses are always reliable, precise and performed thoroughly.

The device used by our company has been specifically designed for the foundry industry, which is where it is required to define the precise composition of the materials.

When smelting metals and alloys of a specified composition spectrometric analysis is very important. Significant progress has been made in automating the process which is reflected in the speed of the analysis. Routine quality control of semiproducts and final products can be made during as well as at the end of the production process using the emission spectrometer.

We have software to carry out the tin and lead alloys based analysis:

- tin,

- lead.

We welcome you to use any of our services.

Please contact our Marketing Department if you have any questions regarding our services.